ValPro maintains an ISO 9001/ API-6D/ API-6A/ API-600 quality management system with strong emphasis on the continual improvement of quality, engineering, manufacturing, and business related processes. The scope of this quality management system covers all processes directly and indirectly related to the design, manufacture, assembly, and testing of our products. Products included in that scope are: stainless steel, carbon steel, special alloy, chrome, iron, and bronze valves.

The quality management system also makes provision for the control of purchased component products, which requires that these suppliers also maintain an ISO 9001 based quality system and the subsequent certification. It is the intent of the company to partner with its supply base in order to develop a strong and continuous relationship that is imperative to the quality, success, and future of the company. Procurement of outsourced processes and services that affect product conformity, such as, RT, MT, PT, and calibration of measurement and test equipment, are also controlled in the same manner.

The procurement process is controlled by specific guidelines and procedures established in the company's quality manual, supporting tiers of procedures, and work instructions. The level of control exerted is dependent on the type of product or service, and the impact on the quality of the final products and services provided to our customer. There are procedures detailing criteria to determine the capability of suppliers, which include the selection, evaluation, and re-evaluation of suppliers. Suppliers furnishing vital materials and products are audited on a regular basis to determine the adequacy of their quality system.

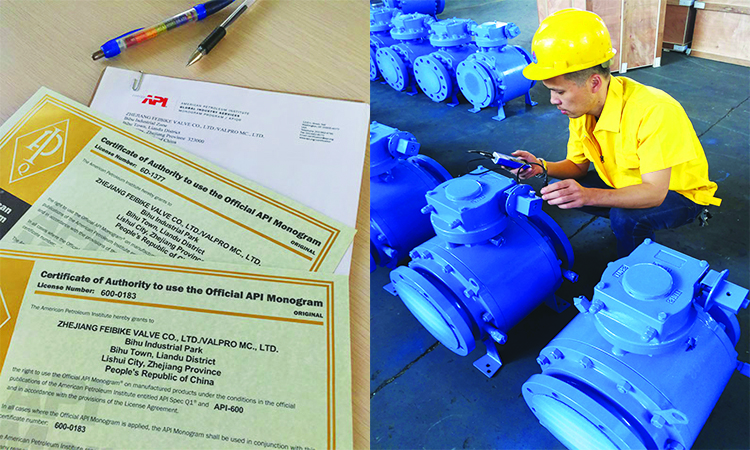

Please see below for our Certificate of Authority:

- API-6D

- API-600

- API-6A

- CE PED

- ISO Certificate

- CRN

- Certificate of Quality System Approval

- Occupational Health And Safety Certificate

- Environmental Management System Certificate

-

Fire Test

- 2" CLASS 150 607 BALL VALVE

- 2" CLASS 600 607 BALL VALVE

- 2" CLASS 600 6FA BALL VALVE

- 4" CLASS 150 607 BALL VALVE

- 4" CLASS 600 607 BALL VALVE

- 4" CLASS 600 6FA BALL VALVE

- 8" CLASS 150 607 BALL VALVE

- 8" CLASS 600 607 BALL VALVE

- 8" CLASS 600 6FA BALL VALVE

- 8" CLASS 900 607 BALL VALVE

- 8" CLASS 900 6FA BALL VALVE